Bunker Survey & Surveyor

View and examine the condition of an object. Bunker Survey is an examination of the ship's fuel to ascertain its total on board quantity. it can be ROB quantity, ROB is Remaining On Board of fuel oils like MGO (marine gas oil) or MFO (Marine Fuel Oil) or LSFO (low sulphur fuel oil) or HSFO (high sulfur fuel oil) or LSMDO (low sulfur marine diesel oil). Bunker Survey is carried out mostly by visual observation, facts finding, about the general data and idea, by measurements, technical matters, etc. and, if needed, provide recommendation. Bunker survey is carried out to measure and ascertain the quantity of Bunker on board at the specific time. This survey is produced the report that states the amount of bunker, usually Fuel Oil (FO) and Diesel Oil (DO), and sometimes Lubricating Oil (LO) is included. Bunker Surveyor is the person who hold a valid bunker surveyor license issued by the implementing authority. Surveyor is the person who conduct the survey, for doing the job, the person is expected to be independent and backed up by sufficient professionalism.

Cappuccino Bunkers

Cappuccino effect remains still one of the most common and widely used ‘mal-practice’ in the bunkering industry to-date. Despite lot of articles and loss prevention bulletins being issued by various P&I Clubs; we are still seeing lot of vessel’s falling victim to this ill-practice. Often our expertise is called upon at the next port of call when the vessel just five days into her voyage after stemming bunkers would discover a sudden “disappearance” of 30-40 MT overnight. It is then too late for us or anyone to do anything!

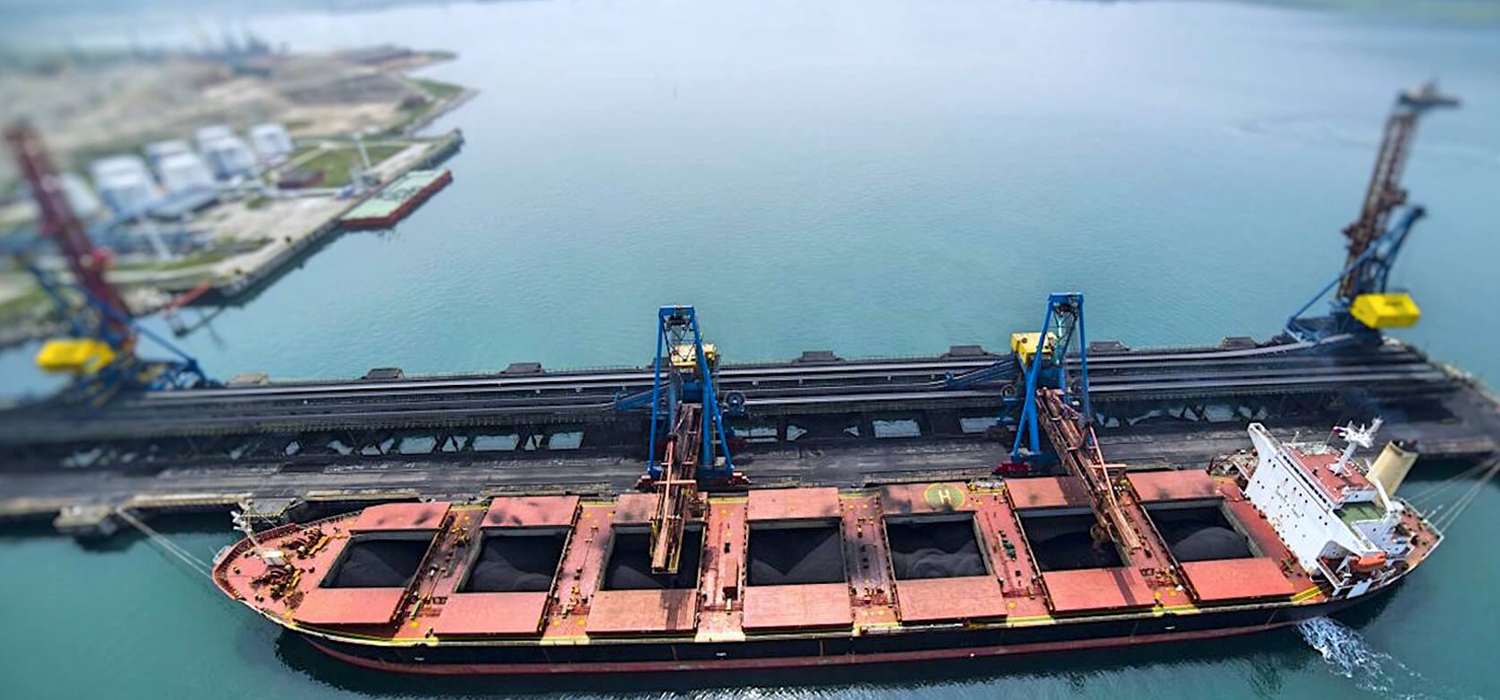

Draught Survey

A draught survey is a method of cargo weight determination by ship’s displacement calculations, empty and loaded (or loaded and empty), taking into account any change in weight of the liquids on board. The accuracy of the draught survey will be dependent upon the experience and the care taken by the surveyor concerned, on the documentation of the vessel, on the spirit of co-operation of the vessel crews and of the shore terminal personnel and, last but not least, on the instruments used by the draught surveyor and the weather and sea conditions in the harbour.

Magnetic Compass Adjustment

Compass Adjustment is the method of analyzing and compensating for deviating forces of a vessel’s magnetic compass. A magnetic compass should always align steadily to the earth’s magnetic field, pointing to magnetic north. However, steel, electronic instruments or equipment, and even the type of cargo carried, can cause the compass needle to point away, or deviate, from magnetic north. Compass adjustment is necessary to compensate these deviating forces with correctors. The deviations on principle headings, typically the cardinal (N, E, S & W) headings and intercardinal (NE, SE, SW & NW) headings are identified, and then correctors are employed to either completely remove or reduce the deviation. Correctors may be permanent magnets or soft iron, which are placed adjacent to the compass. This creates equal, but opposing magnetic fields, thus nullifying the deviating fields around the compass, enabling it to align correctly. Now, the earth’s magnetic field can pass through the compass without being deflected out of its normal path. For various factors such as design, location and the vessel’s unique magnetic properties, all the deviation may not be removed. The residual deviation is recorded on a deviation card as a table or a curve of deviation against the compass headings.